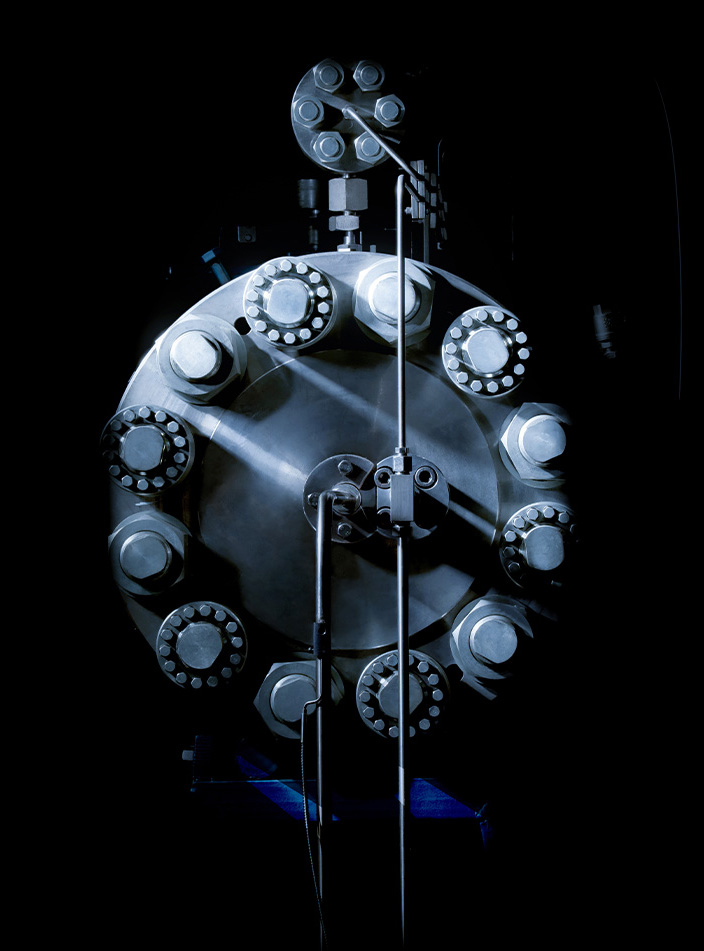

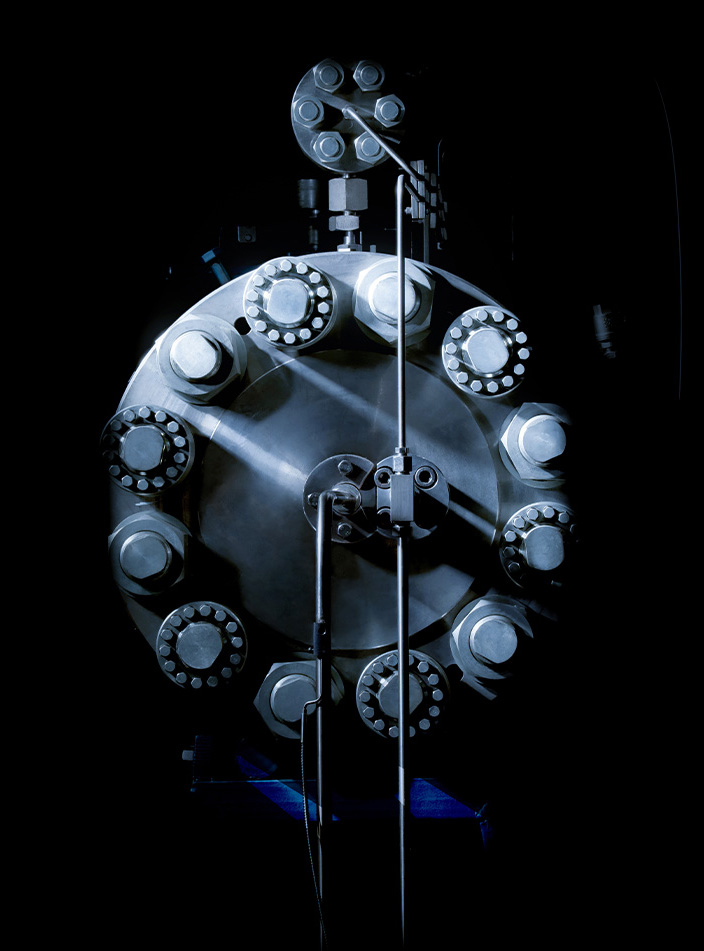

The diaphragm set consists of three metal palates, separating process gas and hydraulic oil completely.The motor transmits the power to the crankshaft system by the means of direct or belt transmission to reciprocate the piston.The piston pushes the hydraulic oil and the diaphragm to sweep the cavity contours to maximize displacement and pressurize the gas subsequently. The diaphragms move back and forth under the control of suction and discharge to finish every compression.

Tiangao diaphragm compressor has excellent sealing performance. Static seal could be achieved between gas side and oil side. The diaphragm set completely separates process gas from hydraulic oil. There is no leakage during compression. Tiangao designed structures and selected materials contrapuntally to achieve the best sealing. During production, we remove pollutants on the metal diaphragm surface and inside the pipeline. The process gas purity could reach 99.99999%. The diaphragm compressor is particularly suitable for compressing high purity, noble, precious, corrosive, radioactive, toxic and explosive gases.

Diaphragm compressor pressurizes by changing the volume of the cavity contours. With a large surface area and volume, the diaphragm compressor can achieve 1:5 to 1:10 economic compression ratio or 1:20 maximum compression ratio. Benefits from its large surface area, the cylinder heat could be dissipated quickly. The compression process is a near-isothermal compression. Even in the condition of high compression ratio, there is no obvious temperature rise during compression that concurrently meets the requirements of high discharge pressure, large flow and low temperature rise.

Optimized cavity contour design. The traditional cavity contour design is based on the Kármán Equations, but the gas flow characteristics of hydrodynamics are neglected. Average diaphragm stress is not the only reason brings better fluidity. Better cavity contour design can improve the volumetric efficiency and increase flow and compression efficiency.

The servo valves could reduce 20% energy consumption and extend diaphragm life. During the operation, the pressure of storage tank influences the pressure of discharge, while oil pressure is changed in accordance with gas discharge pressure. The servo valve allows the oil pressure to be adjusted according to gas pressure, as consequence, the shaft power is adjusted to consume less energy and bring more efficiency.

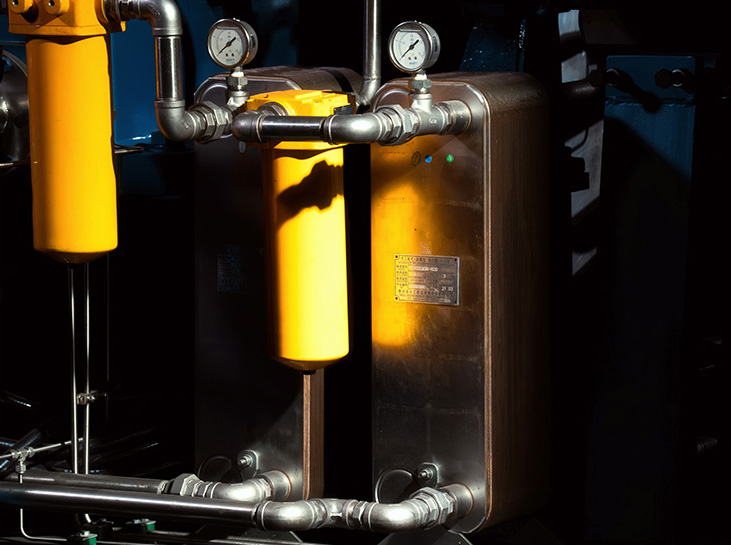

The lower the discharge temperature, the higher the efficiency. Temperature control is an important means to improve operation efficiency. The Oil & Gas Cooling System enhances the efficiency and reduces power consumption. Tiangao has designed multi-layer coolant channels inside the cylinder to cool down the discharge temperature and reduces heat of gas from transmitting to oil to ensure the lubrication effect of hydraulic oil. The Dual Intelligent Oil Cooling System could be installed which can be automatically turned on and off according to oil temperature, better controlling the temperature and saving energy.

Longer diaphragm life and less diaphragm maintenance costs. All designs aim to optimize diaphragm service life and maintenance cost. The normal service life of diaphragm is 4,000-8,000 hours. The longest diaphragm life of Tiangao diaphragm compressor reached 20,000 hours.

2.0 MPa minimum unloading pressure. The hydrogen refueling station can fill 45.0 MPa tanks by diaphragm compressor when the tanks pressure is greater than 8.0MPa and fill 25.0 MPa tanks when the pressure is less than 8.0 MPa without residual gas compressor. The minimum unloading pressure could reach 2.0 MPa, greatly reducing the economic loss caused by residual gas in trailer.